Micro Manufacturing Success: A Guide to Extreme Precision in Production

Introduction

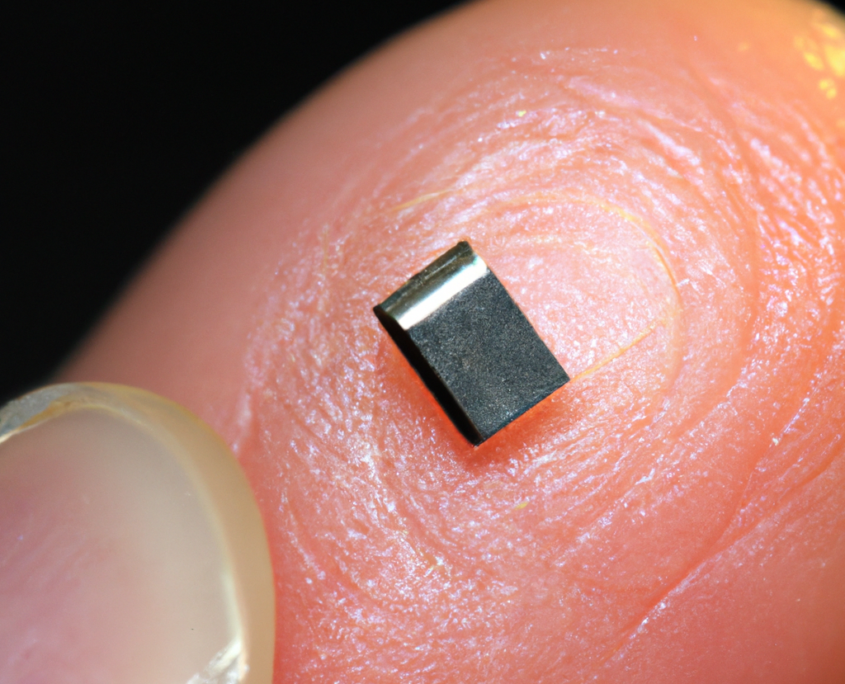

In the intricate world of manufacturing, particularly in industries that demand extreme precision like medical, aerospace, and defense, the phrase ‘smaller, faster, better’ has become a mantra. The micro-manufacturing sector has arisen as a revolutionary force to heed this call. The purpose of this article is to shed light on how businesses can achieve outstanding prototype speed, transition from prototypes to full-scale production, and optimize design for manufacturability. These elements are essential for any company specializing in the design and manufacture of extreme precision components.

The Need for Speed: Accelerating Prototype Production

One of the most crucial aspects in the life cycle of extreme precision components is the speed at which prototypes can be created and put into engineers’ hands for evaluation. The sooner this happens, the quicker the design can be iterated, tested, and approved for mass production.

“Speed is the essence of war. Take advantage of the enemy’s unpreparedness; travel by unexpected routes and strike him where he has taken no precautions.” – Sun Tzu.

While this ancient proverb may seem removed from modern engineering, its wisdom is palpable. Rapid prototyping not only cuts down lead time but also gives manufacturers the competitive edge in today’s fast-paced market. Through precision micro machining and specialized micro manufacturing solutions, designs can be quickly converted into tangible prototypes for immediate testing.

Read More about The Need for Speed in Prototyping

Seamless Transition: From Prototype to Full-Scale Production

The next challenge after achieving rapid prototyping is ensuring a seamless transition to full-scale, bulk micro-machining. The infrastructure that serves for prototype manufacturing should be scalable for mass production. This is where design for manufacturability comes into play. Processes that are highly automated and minimize human intervention result in high-quality components at a lower cost, even for specialized fields like medical micro machining.

Read More about Seamless Transition Strategies

Design for Manufacturability: Aligning Prototypes with Production

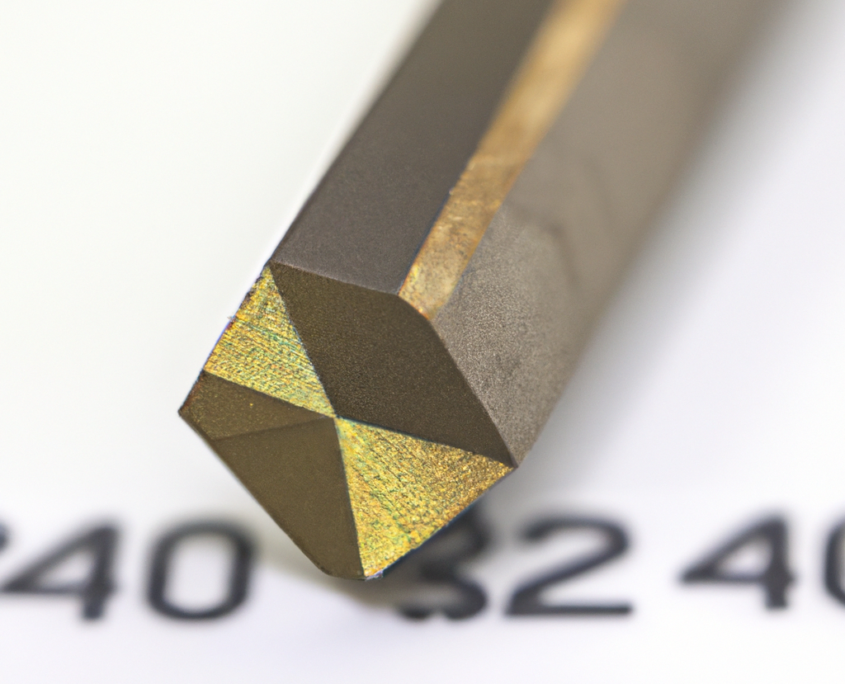

One of the challenges in the micro manufacturing industry is achieving a design that is both innovative and easily manufacturable. An upfront, rapid design work that employs advanced CAD tools and simulation software can help align the prototype and scaled production requirements.

“For every minute spent organizing, an hour is earned.” – Benjamin Franklin.

Investing time in designing for manufacturability not only leads to faster production but also cost optimization. It helps identify potential issues early in the design stage, saving time and resources in the long run.

Read More about Design for Manufacturability

Niche Applications: Micro Spray and Micro Nozzles

In specialized applications, such as micro spray nozzles used in medical or environmental settings, the precision of components can never be compromised. The tiny dimensions demand a high level of expertise in both design and manufacturing. Companies specializing in these niche applications utilize advanced techniques such as laser-based micro manufacturing and ultrasonic machining to meet these stringent requirements.

Read More about Niche Applications in Micro Manufacturing

Conclusion

Success in the world of micro manufacturing is defined by the ability to produce extreme precision components rapidly, at scale, and in a cost-effective manner. By focusing on accelerating prototype speed, ensuring a smooth transition to full-scale production, and optimizing design for manufacturability, companies can set themselves up for long-term success in this intricate and demanding field.

Whether your interest lies in general manufacturing or specialized fields like medical micro machining, the principles remain the same: speed, scalability, and design optimization are your allies in achieving micro-manufacturing success.