MICROMANUFACTURING TECHNOLOGY

Crafts Technology harnesses innovative micromanufacturing processes to achieve unparalleled results.

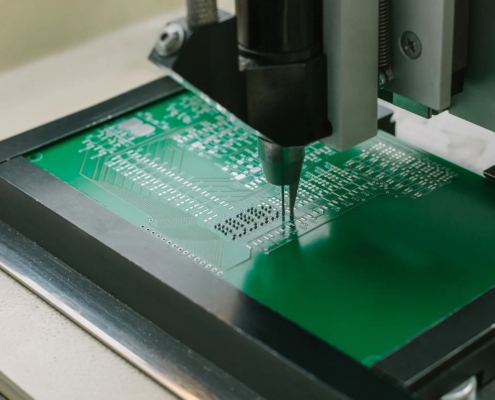

Micro precision machining cells are optimized to produce parts at the prototype level with a seamless transition to full production.

This micro manufacturing system tied with our expertise in advanced materials allows for team to invent new levels of performance and capability.

- State of the art capability in producing features below 25 microns (.001″)

- Surface finish values below .05 microns (2 micro inches)

- Roundness specifications below 3 microns (.0001″)

- Proven production level output, with 6 Sigma Cpk levels above 3.0 at micron tolerances

Micro Manufacturing Products:

- Tungsten Carbide Nozzles

- Micro Manufactured Nozzles

- Medical Micro Machining

- Precision Orifices

Industry Examples:

Performance Meets Micro Manufacturing

Component Life: Determine what is possible with the use of Advanced Materials combined with State of the Art Surface Finishes. This combination on the Micro-Process Level allows for solutions to develop that were previously thought impossible.

Advanced Materials: Ceramic Diamond, Tungsten Carbide, Ceramic, High Hardness Tool Steel, Stainless Steel

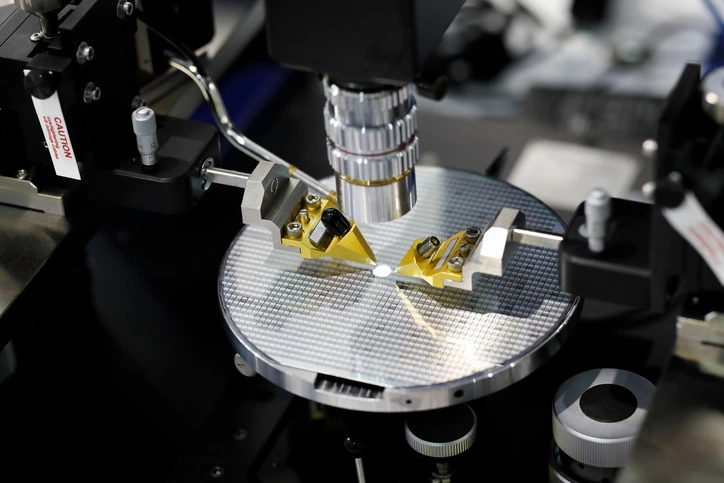

Solutions Achieved in Industry: Micro Chip Production, Medical, Semi-Conductor, Micro Chip, Fluid Dispensing, Aerospace, Automotive, Lab/Test.

Discover the possibilities…