State of the Art Orifice Design & Production

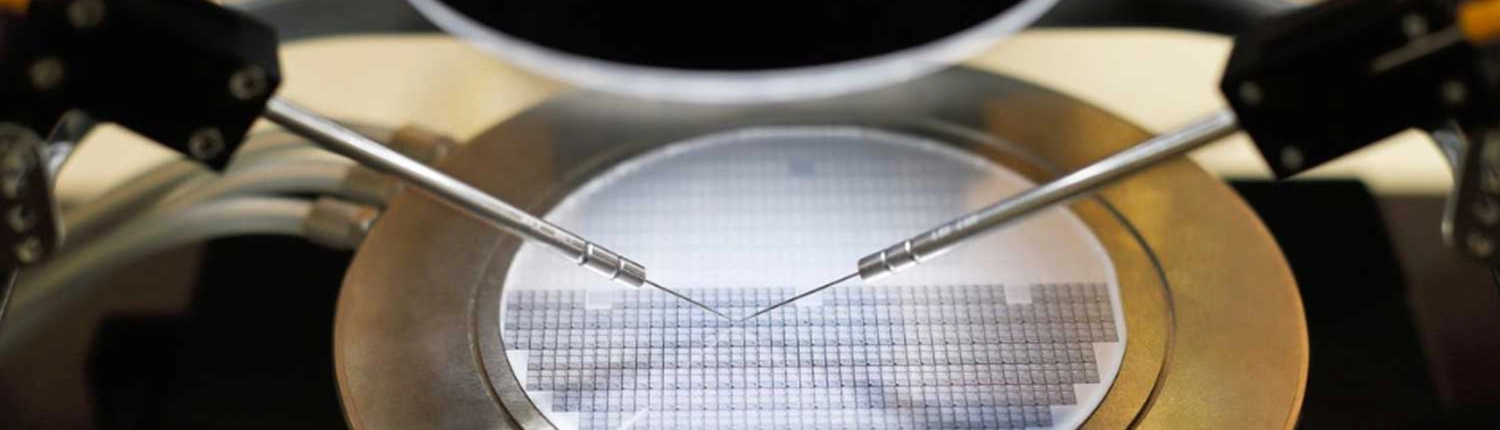

Nozzle and seat orifices are arguably the most critical features within fluid dispensing applications.

The orifice is the last section of the nozzle that fluid travels through, which makes this section the control factor for most outputs of the nozzle.

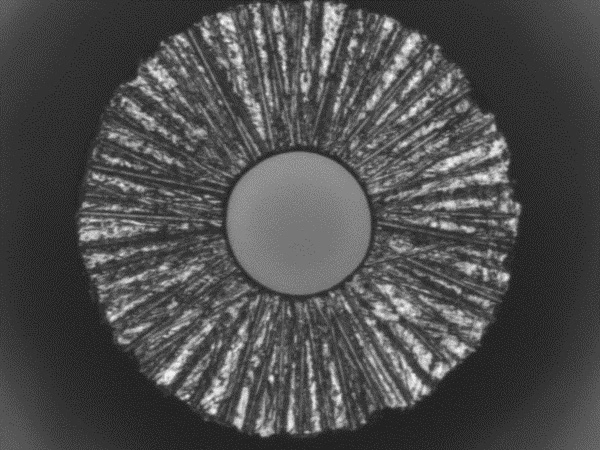

High performance depends on tighter controls in the form of straightness, positioning, wall surface finishes, and circularity attribute to the droplet quality.

The design and fabrication of this feature must be customized to achieve optimum results.

Application Examples:

Sealing Verification

Crafts Technology offers significant experience with in-house fluid testing procedures. To optimize your supply chain, we can perform 100% leakage verification prior to the components reaching your operation.

Leakage validation processes include:

- Custom Fixturing

- Vacuum Pressure Decay

- Low Viscosity

- Water

- Customer Supplied Equipment

Optimized Supply Chain – Kanban System

We partner with OEMs and end users to develop a unique system that can achieve extreme quality and unparalleled response time, while maintaining process exact and tempo (takt time) throughout our operations.

Precision Seal Interface

Sealing of fluid dispensing components requires the mating of the actuator and the nozzle.

We help you design these two mating features to achieve optimum performance.

The following properties are considered when designing the system.

- Volumetric Conditions

- Sealing Capability

- Interchangeability

- Materials Engineering

- Usable Life

Innovative Solutions

Crafts Technology continues to push the boundaries of what is possible for fluid dispensing equipment to address issues involving a variety of adhesives, coatings, sealants, and biomaterials in fluid management. We look at every component as a fresh start, to see what features can be improved and what needs to stay the same.

Our engineering team can work with your team to determine how to leverage our capabilities to develop products that are truly state of the art.

Progressive Applications:

- State of the art capability in producing orifice below 25 microns (.001″)

- Surface finish values below .05 microns (2 microinches)

- Roundness specifications below 3 microns (.0001″).

- Proven production level output, with 6 sigma Cpk levels above 3.0 at micron tolerances.

- Over-molding with Advanced Polymers

- Advanced Materials – Alloyed Diamond

Application Experience

Crafts Technology has been designing and producing critical fluid dispensing components for more than 30 years, working as a partner with our customers to develop solutions to a wide variety of problems, including both extreme conditions as well as nuance failure modes.

- Meniscus Build-Up

- Fluid Volume After Sealing Point

- Sealing Performance

- Inconsistent Dot Size

- Tool Life

- Increased Processing