Reflection: A Manufacture’s Secret to Continuous Improvement

Reflection: A Manufacture’s Secret to Continuous Improvement

Through reflection, you are able to foster a culture of continuous improvement throughout your organization.

At Crafts Technology we practice this process of reflection to instill a culture of continuous improvement throughout our operations. Within this article we will take you through our reflection process and how it establishes the drive to always be better!

Traditionally, reflection has been directed at the individual. A multitude of self-help business books validates this. (And see the article, “The Power of Reflection,” by Kevin Daum of Inc. 500 to get a quick 10 bullet list of the advantages of having a process of reflection for the individual.)

Although there are benefits for an individual, we believe a larger benefit can be achieved when the process of reflection is applied to an entire organization. With reflection, you review the recent steps that have been taken in the pursuit of one’s goals. Through such a detailed look at the steps that were taken, you are able to garner a highlighted level of understanding of what you went through and where it took you.

Through this reflection process we are able to develop an in-depth understanding of the following questions:

Were the steps we took the correct ones?

What could we have done better?

Did these steps lead us to our original goal?

Have our goals changed?

With these questions answered, you are now in a position to handle what comes next to for the organization. As you fully understand where you have been, where you are, and where you want to be.

When you break down this idea of reflection, at its essence, is a mentality of CONTINUOUS IMPROVEMENT.

And what is every company in the world looking do? … Improve.

For those reasons, we at Crafts Technology believe that through reflection, you are able to achieve a culture of continuous improvement.

As an employee-owned company, Crafts Technology practices regular reflection to instill continuous improvement throughout our organization. As a manufacturing and engineering entity, we must continue to get better through processes such as reflection to stay at the cutting edge of technology and efficiency in order to provide the greatest value to our partners.

The process of reflection pushes all individuals throughout our organization to analyze what has occurred in the past. As a team, we review the steps that were taken over the past year. Through this process, we are working to generate reflection within every member of our team to instill a mentality of continuous improvement that will allow for the achievement of our company goals.

We focus on:

- How do we learn from our mistakes and get better for next year?

- What are we proud of?

- What made us want to come into work each day?

- Are we able to leverage the advancements we made in other areas of our organization?

- Are we working towards and achieving our goals?

This reflection process serves as an opportunity to develop answers to each of these questions. With these answers, every member of our team is equipped to be better in the future.

Our reflection process focuses on 4 areas:

People and Culture

Our Partners

Design Innovations

Operational Efficiency

People and Culture

Our major focus of the review is the PEOPLE of Crafts Technology. We look to highlight events throughout the year that are great learning opportunities, good or bad. We focus on achievements, losses, and connections with our cultural values in a way that promotes the improvement of the organization. Please see Crafts Technology’s Culture of Ownership Page for reference on our values.

Key Areas:

- New Members

- Transitions: Retirement or Promotion

- Legacy

- Cultural Development

A few pictures from our latest reflection on our People and Culture:

New door sign on all entry points to showcase our mission and values.

Legacy: Review Employees Tenure with the Company

Our Partners

The second area of focus is our partners, the organizations with which we do business. These organizations allow us to function and make what we do worthwhile.

Through our yearly review, we highlight our partners’ successes in the marketplace and demonstrate how Crafts facilitated support of that success with our products and engineering solutions.

Many times, the end accomplishment of a product or solution can be lost when each team member is performing individual steps in an extended process. By presenting the connection of what Crafts products and solutions have helped attain in the marketplace, our team members understand the success their work is achieving. This facilitates a sense of pride in the work all of our team members perform.

In addition, Crafts also works to be involved in our partners’ charity events to support the world around us. We present our partners’ successes in this endeavor and demonstrate how we helped support these causes.

Lastly, we review any recognition Crafts has received from our partners as every member of our team was critical in achieving these awards.

Key Areas:

- Success of our partners and how Crafts has helped support that success.

- Our partners’ charitable contributions and Crafts’ involvement.

- Awards Crafts has received from our partners.

Two of the awards Crafts Technologies has received recently include the Nordson’s David S. Miller Quality Award and the Entrepreneurial Excellence Award for Innovation

A few pictures from our latest reflection on our Partners:

Nordson David S. Miller Quality Award – 2018

2018 Entrepreneurial Excellence Award for Innovation

Stay Up to Date on the Innovations from Crafts Engineering & Manufacturing Team

Stay up to date with informative articles from Crafts Technology Engineering Team every other Month.

Articles cover all that Crafts is, making sure to share our knowledge for the betterment of the world’s industrial equipment.

Categories include:

- Engineering Design

- State of the Art Manufacturing

- Lean Manufacturing

- Cultural Development

- Social Impact

Bonus+

Crafts Technology SuperHard Material Properties Guide

Included with Sign Up!

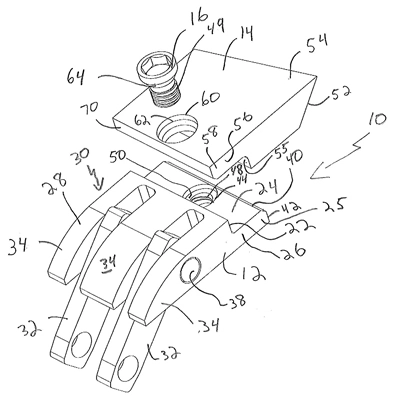

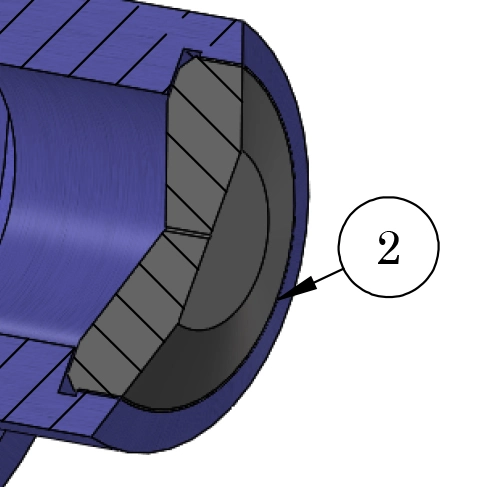

Design Innovations

At Crafts Technology, we are experts in both the engineering and manufacturing of solutions. Our engineering team works with our partners to enhance the performance and utilization of industrial equipment. This same engineering team has a unique ability to review the solutions with our operations team to incorporate a high level of design for manufacturability into each solution from the beginning.

Within our review, we cover new designs, innovations, and materials with our entire organization. We want to review new developments with the entire organization and how they will impact the organization. We have found that this review promotes a Culture of Innovation as the entire company understands why change is occurring and takes it head-on.

Key Areas:

- Enhanced Products

- New Designs

- New Materials

- Patents

A few pictures from our latest reflection for Design Innovations:

Operational Efficiency

Crafts Technology must stay at the cutting edge of manufacturing efficiency to provide the greatest value to our partners. We work to implement state of the art enhancements in our operations to continually elevate our position as leaders in the marketplace.

Through reflection on the projects that have been implemented over the past year, we are able to demonstrate the advantages these projects have achieved. This develops a connection of improvement within the entire organization that can be leveraged throughout the organization.

Key Areas:

- New Equipment

- New Facility and Office Layouts

- Training

- Visual Management Tools

A few pictures from our latest reflection on our Operation Efficiency:

Capital Equipment: CNC Surface Grinder

Capital Equipment: OD Grinder

Conclusion

Crafts Technology secret to Continous Improvment is regular reflection.

We practice reflection to understand what we have done, what goals we have achieved, and where we are going.

This promotes a Culture of Improvement throughout our entire organization.

Please contact us to learn more about our reflection process or how this culture can be harnessed to enhance your Industrial Equipment.