PRECISION MICRO NOZZLES AND CARBIDE NEEDLES

-

Highest precision less than 2-micron tolerances

-

Highest repeatability greater than 3.5 cpk levels

-

Rapid Prototyping: 3 weeks

-

Greatest ability to scale quickly

-

Reverse engineering current offering; dramatically reduce consumable cost

Designed for Flawless Operation

Our design engineers take into account the critical dimensions of each nozzle and needle to perform optimally within their environment.

We harness our long experience within the fluid dispensing space to design and produce the highest performance and longest lasting tooling on the market. This includes carbide nozzles, carbide needles, precision orifices, and micro orifices.

Orifice Precision

Size and tolerance are the well-known governors of fluid dispensing performance quality.

Our state-of-the-art capabilities can achieve world-class precision and performance.

- Micro Holes: State of the art micro manufacturing capability in producing orifices below 25 microns (.001″)

- Extreme Finish: Surface finish values below .05 microns (2 microinches)

- Micro Holes: Roundness specifications below 3 microns (.0001″).

- Micro Holes: Proven production level output, with 6 sigma Cpk levels above 3.0 at micron tolerances.

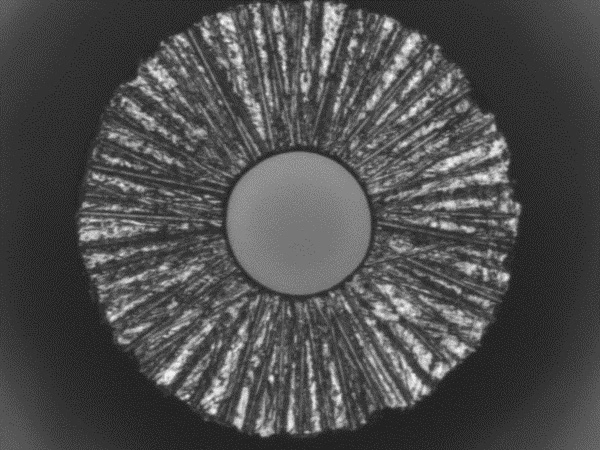

Roundness Precision

The roundness of the orifice is critical to the fluid dispensing performance and quality. Especially when dealing on the micro nozzle scale.

Many manufacturing methods leave elongated or inconsistent shapes that can have negative effects during operation.

At Crafts Technology, we understand that the right micro-manufacturing method is required to achieve the desired results of roundness in the micron range.

Surface Finish Precision

The surface finish on the inner wall of the orifice is a lesser-known critical feature of the micro nozzle.

This feature is very difficult to check without destructive testing and can contribute to large variations in fluid dispensing performance and flow quality.

Crafts Technology employs a precision manufacturing process that achieves uniformity and optimizes finish values over the full length of the micro orifice walls.

Application Life

The goal of Crafts Technology is to produce nozzles and needles that will deliver the most consistent fluid dispensing performance over the longest life.

Each of the following design aspects must be addressed at the time of initial design to achieve the desired results.

- Carbide Nozzle Funnel Profile/Straightness

- Carbide Nozzle Funnel Surface Finish [Sa]

- Carbide Needle Sealing Area Roundness

- Carbide Needle Sealing Area Surface Finish [Sa]

- Optimize Material Selection of Each Component

Work with Crafts engineering team to develop optimum solutions for each of the considerations above.

We invite you to consult with our engineering team to develop optimum solutions for your fluid dispensing applications.

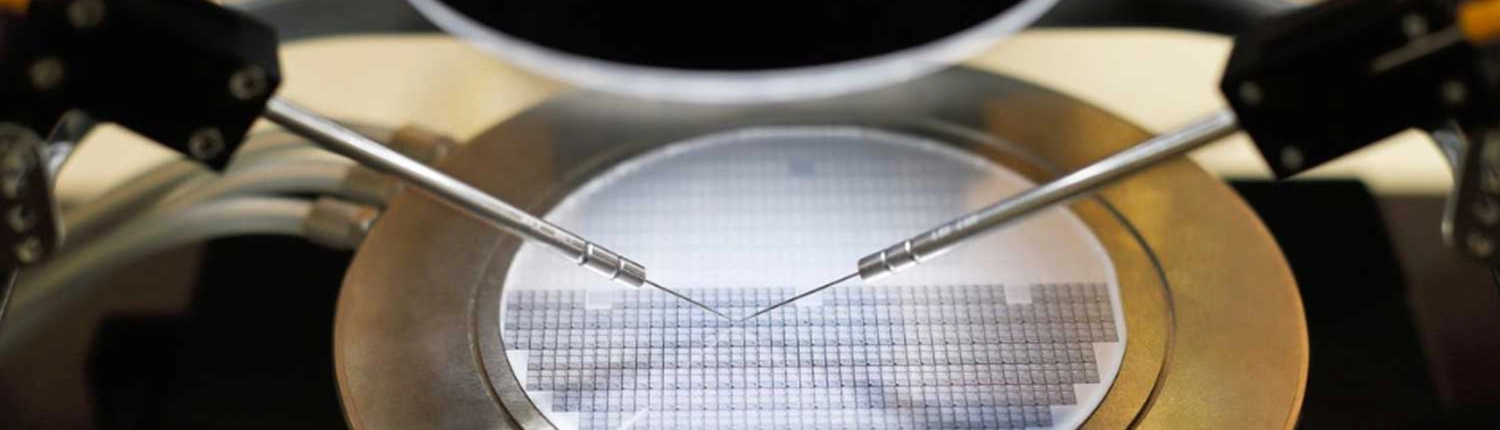

Industry Example:

Our Engineering Team is standing by, ready to discuss your application!

Positioning Precision

The position of the orifice & micro orifice relative to the overall assembly is important to nozzle performance.

With complex tolerance stack-ups that affect the function of the overall system, the accuracy and precision of the carbide nozzle are crucial to fluid flow and location.

Crafts Technology has the capability to produce nozzles that result in positional accuracies below 5 microns (.0002″). Our manufacturing processes allow components to be produced that are both high quality and high precision so that your system can achieve unparalleled accuracy.

Length : Diameter (Aspect Ratio)

Aspect ratio is the relation between the diameter of the micro orifice and its length [depth].

Manufacturing design for WC nozzles and WC needles must take into account key operational considerations, such as the longer the aspect ratio, the greater the laminar flow through the orifice. Higher aspect ratios present increased difficulty to produce and can introduce undesirable feature such as tapers.

Crafts Technology engineers can help develop the desired micro orifice aspect ratios through design for manufacturability and our state-of-the-art manufacturing methods for ultra-hard materials.

Innovative Solutions

Crafts Technology continually pushes the boundaries of what is possible with precision manufacturing of superhard materials.

Our experience includes innovation in the development and production of the following:

- Micro Orifices & Micro Shapes below 25 microns (.001″)

- Surface finish values below .05 microns (2 microinches)

- Over-molding blending Advanced Polymers with Ultra-Hard Material

- Alloyed Diamond for massive enhancements in component life, repeatability, and performance.