State of the Art Manufacturing

Our manufacturing facility, located near Chicago’s O’Hare International Airport, serves clients with national and global markets. We are continually upgrading our technology and training our people to produce outstanding results and to provide responsive customer service.

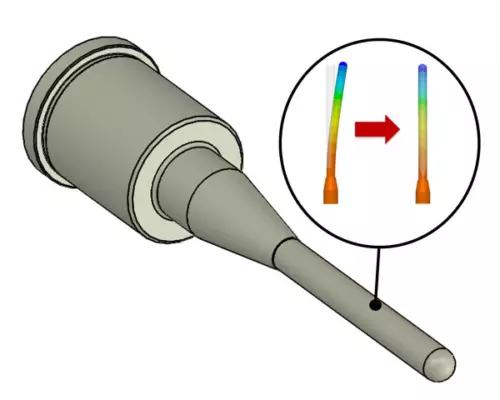

We operate the largest collection of micro-EDM [Electrical Discharge Machining] machines in the world in order to meet your micro-production demands and offer services from prototype to full production of micro-scaled components and sub-assemblies. Our high-precision manufacturing capabilities also include inspection with Micro-CMM (Coordinate Measurement Machine) with proprietary capabilities to inspect features that others cannot, and Zero Force manufacturing to protect the precision of the component and assemblies.

Partner with us to understand and tap into these capabilities, and see how they can be harnessed to produce solutions that you did not believe were possible.

Engineering / Innovation

Transformational engineering balances materials science, engineering design, and manufacturability to develop novel approaches that optimize every aspect of our partner’s value stream.

We have developed co-patented solutions with our clients to outperform the competition.

We deliver comprehensive technical support from start to finish and beyond, encompassing expert material selection and design assistance, failure modes analysis, as well as ongoing engineering support and continuous improvement efforts.

Materials Science

Crafts Technology is known for application engineering that assists customers in identifying the optimum material for the development of products that will provide the best performance and the least cost method of manufacturing.

We offer expert technical support from engineers and metallurgists, who consult with the design engineer and advise as to the optimum materials and grades for the application.

Our specialty is working with superhard materials, including tungsten carbide, ceramics, polycrystalline diamond (PCD), advanced polymers, and superior hard steels. By harnessing these materials properly, our clients can achieve unmatched results.