Tolerances

- .0001″ (.0025mm) increments in dimensional tolerances

- .1 degree increments in angle tolerances

- Geometric tolerancing & positioning that align with your system

- Innovative approaches to stack up tolerances

- Unparalleled quality assurance

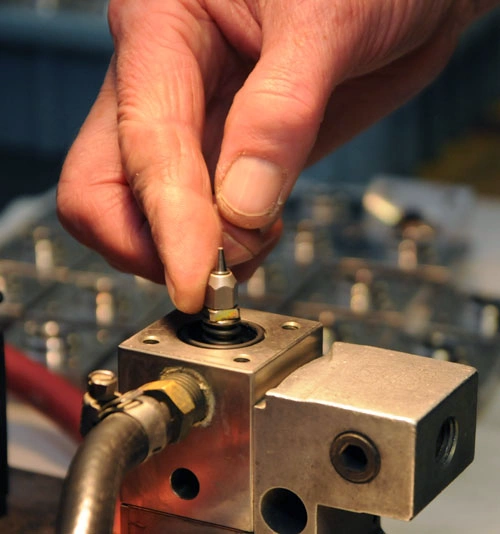

Micro-Manufacturing

- Orifices smaller than .001″(.025mm)

- Complex shapes below .001″(.025mm)

- Production level quality with Cpk values above 3.0

Application Examples:

Prototype – Pilot – Production

- Experience in the transition of each phase; from prototype to production

- Scalability; rapid prototyping to achieve testing milestones, with strong experience in seamless pivoting to full production.

- Design Six-Sigma quality into the system as it evolves

- Advanced flexibility in prototyping

Design for Manufacturability

- Integrate state of the art fabrication technology into your design

- Quality assurance into the components & subassemblies from the start through design for manufacturability.

- Focus on design for each aspect of the value stream – manufacturing, life, recycle.

Supply Chain Optimization

- Systematic Kanban solutions

- Customer portal integration

- Systems to respond to demand fluctuations

- Ability to pivot; based on customer preference

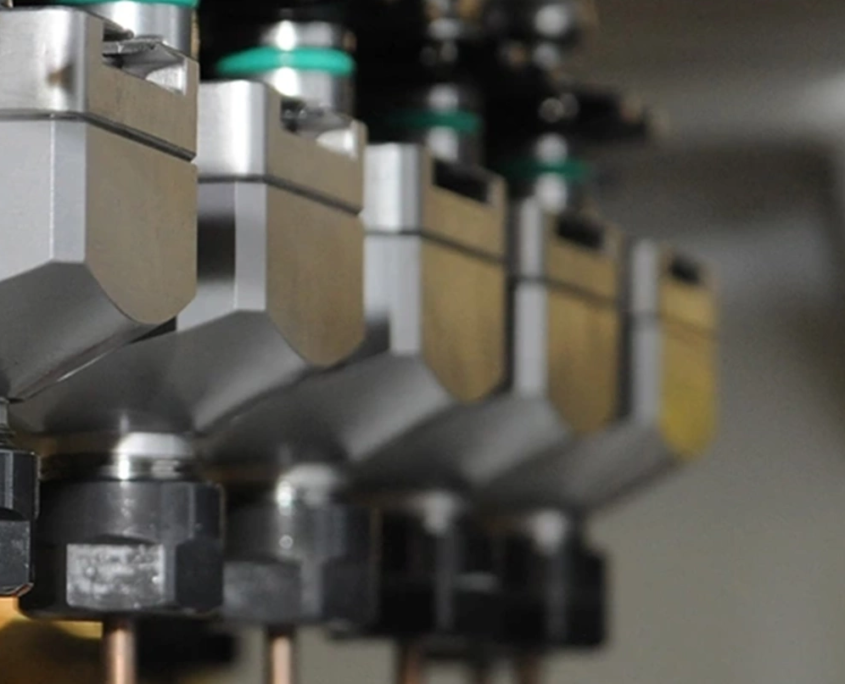

State of the Art Equipment PlayBook

Crafts Technology has developed a strategic method of analyzing cutting-edge technology to see how it can be applied to your applications and their unique requirements.

With this playbook, we aim to always stay ahead of the competition in every area of our operation.

This allows us to provide the greatest advancements in performance, quality, and delivery, year after year.