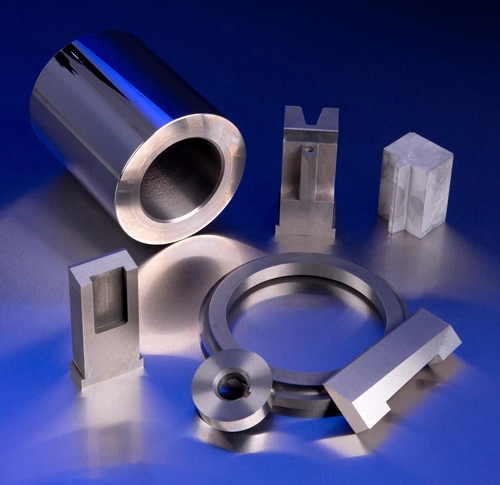

Superhard Wear Parts

At Crafts Technology, we understand how to employ superhard materials in wear parts to reduce your production equipment downtime and deliver a competitive advantage. Many of the world’s largest manufacturers trust Crafts Technology because of our unique ability to provide innovative solutions to severe wear and corrosion problems.

We understand the technology, the materials, and most importantly, the process to identify and implement a superhard material solution that will provide a reduction in equipment downtime.

Refurbishing – Value Stream Engineering

Tooling life can be dramatically increased through the refurbishing of precision components and sub-assemblies.

We can develop a custom refurbishing system for your application that delivers significant cost savings with no negative effect on performance.

Our system provides an analysis of every stage of the value stream from just-In-time inventory management to packaging and ergonomics of tooling returns and replacements.

Discover the possibilities.

Our Engineering Team is standing by, ready to discuss your application!

Expert Material Selection – We work with you to select the most appropriate grades of CraftAlloy™ tungsten carbide and CraftAlloy™ advanced ceramic materials to meet your exact requirements.

Application Engineering – Our extensive experience with knife edges and surface finishes means products are engineered for top performance.

Precision Fabrication – Our flexible, in-house manufacturing can accommodate varying quantities without compromising our rigid quality standards.

Technical Support – We offer one of the most comprehensive support systems in the industry, covering design and engineering assistance, failure analysis, educational seminars, technical papers, and continuous Improvement efforts.