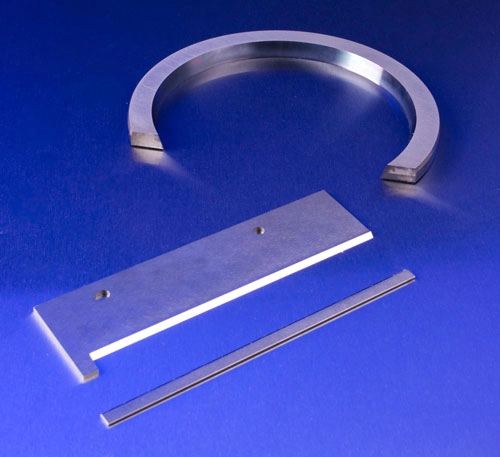

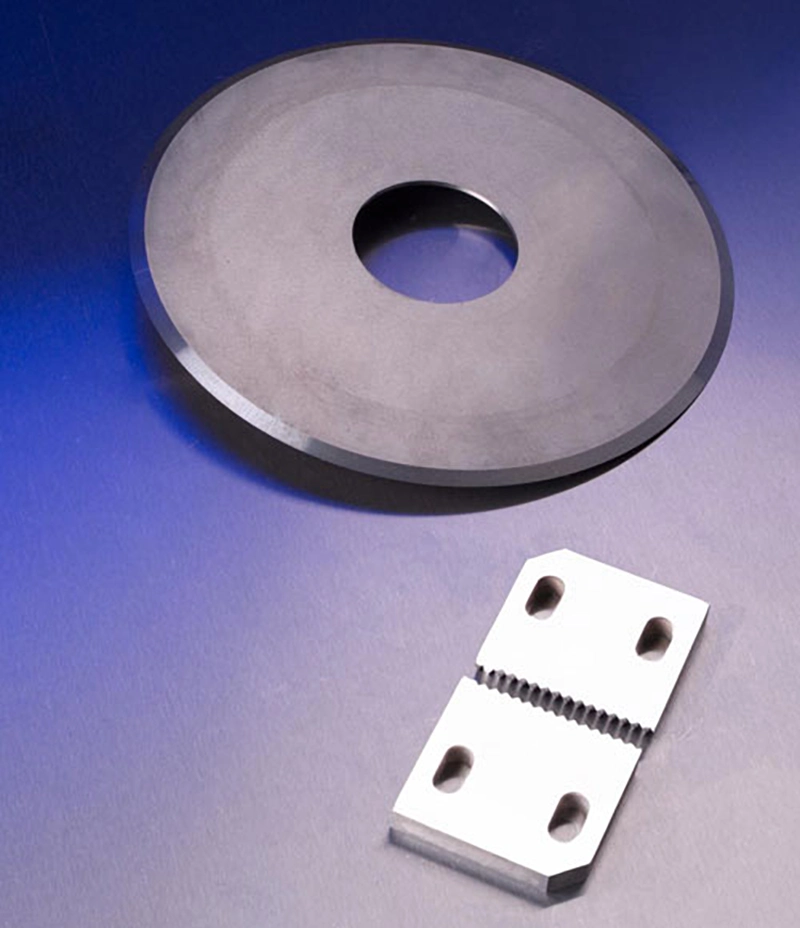

Crafts Technology has been producing high-precision cutting blades, knives, anvils, slitters, and many other cutting implements from superhard materials for the non-wovens industry for more than 100 years. We specialize in high-precision tungsten carbide cutting implements that are typically used to cut non-woven materials, such as those found in diapers, wipes, carbon fiber tape, rubber composites, and other products. Crafts Technology offers specialized wear part and material cutting tools for many different industries.

The following are a few examples of the industries where we have extensive experience working with nonwoven materials:

Expert Material Selection – only optimum grades of CraftAlloy™ Tungsten Carbide and Advanced Ceramic materials are selected for your exact requirements.

Application Engineering – our extensive experience with knife edges and surface finishes means products are engineered for optimum performance.

Precision Fabrication – our flexible, in-house manufacturing will accommodate varying quantities without compromising our rigid quality standards.

Technical Support – one of the most comprehensive in the industry covering Design and Engineering Assistance, Failure Analysis, Educational Seminars, Technical Papers, and Continuous Improvements.

Diapers / Wipes

In the production of wipes, diapers, and similar non-woven materials and products, global manufacturers are looking to increase processing speeds and reduce the Total Cost of Ownership.

Superhard materials and innovative blade designs are the key to minimizing the Total Cost of Ownership. We develop collaborative relationships with Fortune 100 end-user companies that want to maximize their production, and we partner with the highest quality OEMs focused on minimizing the TCO for end-users of their equipment.

Automotive

The automotive industry depends on high-performance cutting implements for such operations as milling the grooves in v-belts and cutting the camber on the side of the belts.

Minimizing the TCO for automotive industry manufacturers has been a primary directive for more than a century and remains so today.

Cutting tools and knives deliver high performance when made from superhard materials for the most effective cutting edges and maximum utility.

Aerospace

The aerospace industry relies heavily on cutters to keep up with production on aircraft.

Extended wear life is absolutely critical to production so that uptime is maximized and production time is minimized on multi-million-dollar Automatic Fiber Placement (AFP) machines and Composite Tape Laying Machines (CTLM).

Leaving these high value machines idle due to unnecessary or premature tool wear is not an option. Crafts Technology has been producing cutters, cutting tools, knives, and other parts for use in the production of composite tape and the fabrication of composite materials since the early 1970s, when McDonnell Douglas was developing composites to reduce the weight of fighter aircraft.

We continue this tradition and leverage our legacy of experience in the aerospace industry, contributing to the efforts of the major aircraft producers to standardize composite technology on new generation commercial aircraft. Crafts Technology develops cutting implements to provide maximum value-add to our customers as they look to improve their competitiveness.