Modular Composite Countersink Drilling

Modular: Replaceable Insert & Drill

Easily Replaceable Insert and Drill

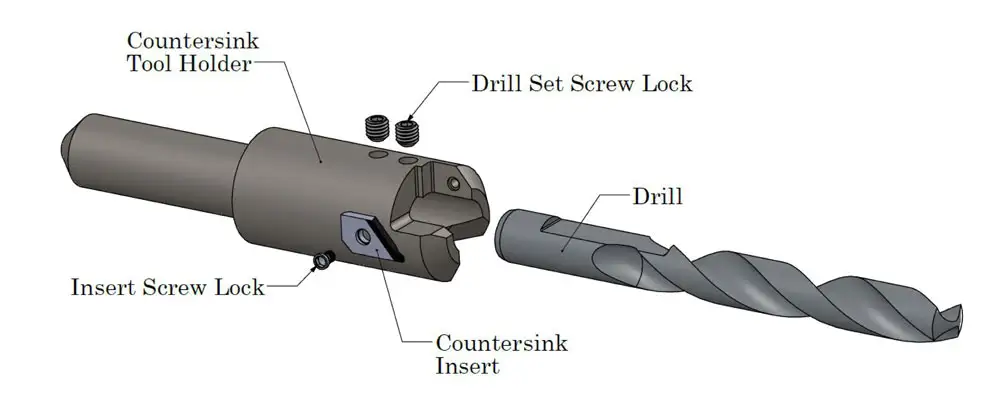

Crafts Technology solutions are made of three components: drill, insert and holder. Each component is designed and produced with specific tolerances to achieve near-perfect run-out as a complete assembly.

This solution allows for a dramatic cost improvement over integral (solid /single-piece) designs by offering seamless replacement of inserts and drills only.

Solutions can be developed that achieve a variety of criteria for your application. We will be happy to work with you to optimize your drilling operations.

Credit: assemblymag.com

Engineered for Your Exact Requirements

Crafts Technology tailors solutions to fit your critical requirements.

The first step is to work with you to determine your exact specifications. We then develop prints and models that conform to your design criteria. These models can be used within your system to validate form, fit and function prior to production.

We work with leading drill manufactures to validate the mating of the drills into our precision holder system. As a result, the complete system achieves the highest measures of quality, repeatability and cost efficiency.

PCD / Carbide Countersink Inserts

Countersink inserts are designed with the use of superhard materials such as CraftAlloy™ tungsten carbide and polycrystalline diamond [PCD]. The choice of material for the insert depends on the material being machined.

Carbon-Fiber-Reinforced Composite/ Aluminum:

The use of CraftAlloy™ polycrystalline diamond (PCD) can achieve an optimal combination of countersink surface finish and tool life. Typical tool life can be more than four times longer that of tungsten carbide.

Titanium:

Crafts Technology produces custom tungsten carbide inserts for the machining of titanium or layered and laminated materials.

Complex Countersink Features

Countersink inserts are designed with precise specified shapes and angles to achieve a unique set of criteria, which can be produced in either PCD or tungsten carbide.

Upon finalizing a design, small batches are produced for validation. Once the parts are validated, we evaluate the supply chain management need in order to develop Kanban systems with intervals that optimize delivery.

Credit: www.assemblymag.com