At Crafts Technology, we understand that today’s highly competitive automotive market demands innovation and high-tech solutions, as manufacturers and suppliers must constantly adapt to meet increasingly stringent automotive standards while boosting productivity and flexibility. Our engineering and design team will work with your team to advance your tooling offerings through custom components and sub-assemblies, delivering a competitive edge in productivity.

Application Specific Design

We focus on being an extension of your team so that you can leverage our expertise in employing superhard materials for automotive applications.

We begin with a full review of your goals in order to develop innovative solutions that blend your demands for optimal cost, quality, and ergonomics.

Superhard Materials for Automotive Applications

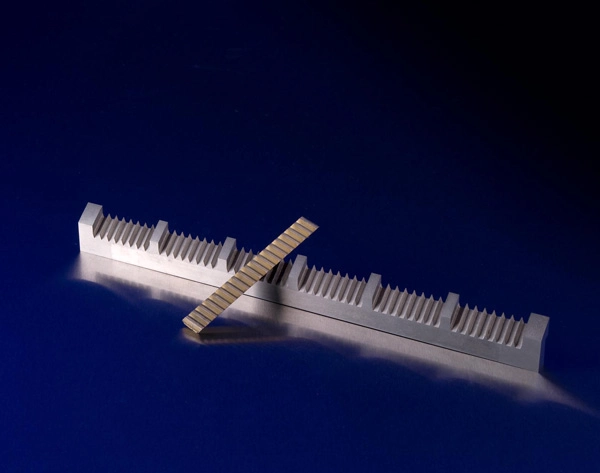

Crafts Technology offers deep experience in producing custom wear parts, components and sub-assembles for automotive equipment, balancing the toughness and hardness of superhard materials, such as polycrystalline diamond, tungsten carbide, advanced ceramics, and high-strength steel.

Of course, there are pros and cons with each material choice. We will be happy to brainstorm with you to select the optimal material for your application in order to maximize the performance of your equipment.

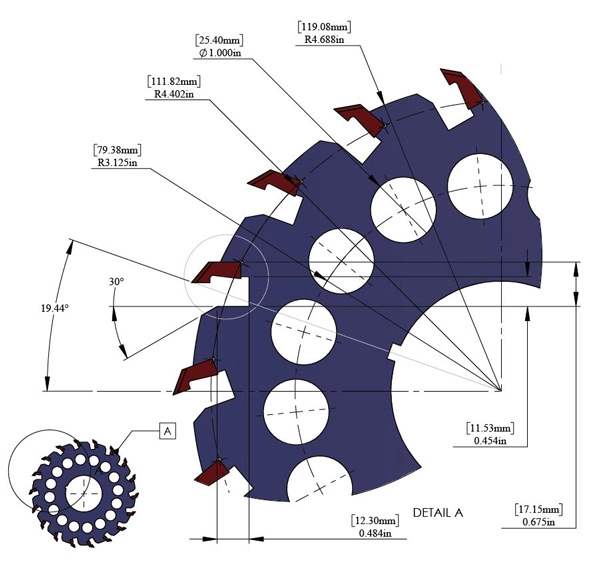

Design & Build of Custom Automotive Sub-Assemblies

Traditionally, harnessing superhard materials for industrial automotive wear parts has focused on producing individual piece parts that must be assembled into the final component. Crafts Technology has the unique ability to produce high-performing complete sub-assemblies that deliver both higher quality and savings in production time and costs.

Depending on the application, we may design a process that performs many of the piece part fabrication steps after assembly. This approach achieves GD & T principles that would not have been obtained through traditional piece part assembly.