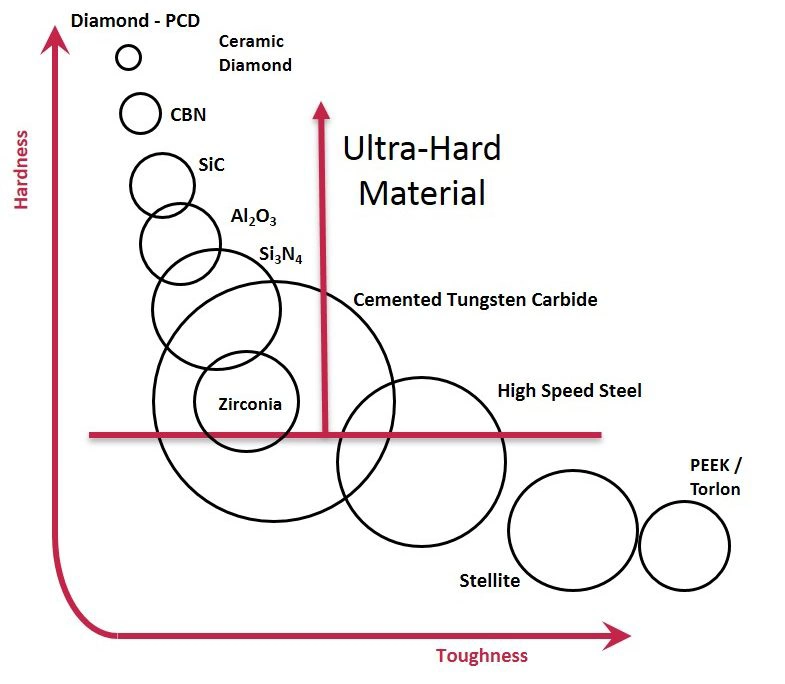

CraftAlloy™ Polycrystalline Diamond [PCD] is man-made diamond, making it one of the hardest engineered materials.

Possessing this superior hardness when compared to all other materials, PCD can be utilized for applications where ceramics and tungsten carbide fall short, especially in the machining of non-ferrous materials.

PCD has become the preferred choice for fabrication of composites, particularly for the machining of carbon-fiber-reinforced composite.

When a PCD component is designed and manufactured properly, the life and quality of the machining cannot be matched.

Work with Craft Technology’s engineering team to design solutions that harness PCD’s strengths and achieve wear life, quality, and cost metrics that were not previously possible.

Application Examples: