How Crafts Technology’s Modular Composite Countersink Drilling Solutions Reduce the Cost Per Hole in Aerospace and Automotive Applications

Countersink tools are used in the aerospace and automotive industries to produce holes that allow fasteners to sit flush to the surface on advanced composite and aluminum applications. Integral countersink drills consist of a single piece that produces countersink holes. Crafts Technology has successfully reduced the cost per hole by designing a modular system with no adverse performance effects.

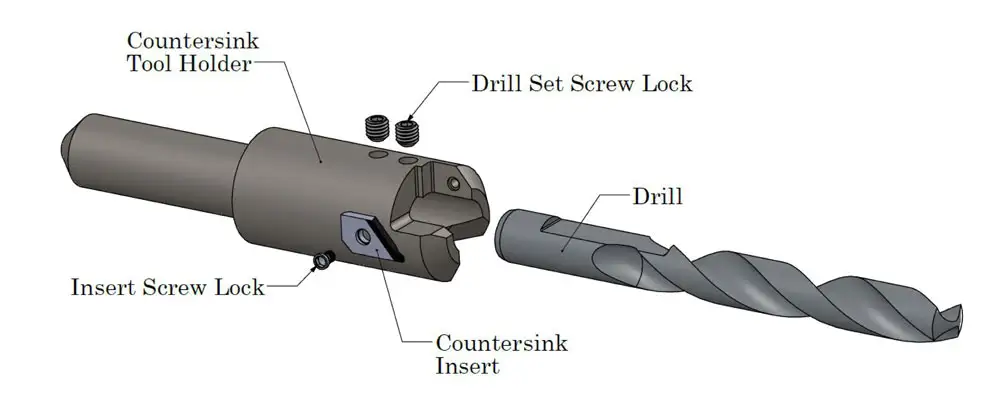

Crafts has been perfecting modular countersink drilling for decades. The modular component includes a holder, insert, and drill. According to Jeff Roberts, vice president of engineering, “Our solution has revolutionized countersinking applications by allowing the end-user to systematically refurbish the countersink inserts and PCD drills, which reduces changeover time and overall cost.”

Over the years, our experience and continuous improvement culture have developed alongside the exponential growth in composite usage, particularly within the aerospace sector. Today, the most technologically advanced companies from Silicon Valley to the largest airplane producers in the world incorporate modular countersink tooling.

Holders are engineered and manufactured per application using customer specifications and the highest quality materials. The modular design allows users to harness current drill solutions without changing engineering/production specifications. At Crafts, we have successfully created modular designs that substantially reduce tooling costs for various clients, including major aerospace companies.

As a design leader, we embraced continual improvement, which has resulted in improved runout, ergonomics, and regrinds. Our ongoing experience has allowed us to pioneer design changes like converting existing product-specified drill tips to straight shanks within a modular system that maintains the validation process.

Crafts always provides modular composite countersink drilling parameters and prototype assemblies to clients to confirm each component works seamlessly as a complete solution. End-users understand that incorporating modular engineered systems allows for dramatic cost improvement over integral (solid/single piece) designs by seamlessly replacing inserts and drills. A recently released white paper, “Modular Composite Countersink Drilling for Aerospace and Automotive Applications: Optimizing Cost per Hole”, further describes how we reduced the cost of tooling for a major aerospace company.

By partnering with Crafts, a company that has been perfecting this technology for years, your tooling life can be dramatically increased by refurbishing precision components and sub-assemblies. Our system provides an analysis of every stage of the value stream, from Just-In-Time [JIT] inventory management to the packaging and ergonomics of tooling returns and replacements.

Discover the possibilities and learn how Crafts can develop a custom refurbishing system for your application that delivers significant cost savings.